Applications:This combois applicable to screenand filter thepowder, particle and abrasive materials in foodprocessing, chemical, pharmaceutical, grinding, ceramic, and metallurgy industries in liquid form or viscosity materials.

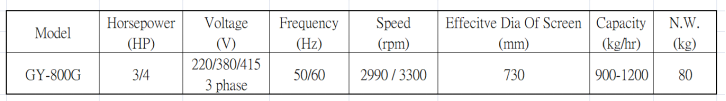

Technical parameters

Features

Small size, light weight, easy to move, and the height can be adjusted freely.

High screening precision, high efficiency, applicable to any powder, particle and adhesive liquid materials.

The vibrating frequency is up to 3000 times/min; the unit can achieve more obvious screening effect when screening materials with fine granularity and high viscosity.

The unique mesh structureisconvenient and easy to installand change the mesh.

All components of this unit excluding the motor are made of stainless steel.

Structure

M14*45 Handle-bar

Caster Wheels

The machine height is adjustable

M8*40L Black knob

M12 Black knob

Prior to operation

Check whether the machine model and specifications are the same as your order?

Is there any damage of the machine during transportation?

Ensure all the components are fastened, no broken on the sieves, no damage on the machine body, electrical cables are connected properly. Power supply is the same as shown on the machine plaque (Tolerance for voltage is ±5%)。The ground lead must be installed firmly.

Note

Ensured the power switch (knife switch is not allowed) and ground lead installation contact well.

It is strictly prohibited to have the motor run with fault phase, or the motor may be get burnt.

This machine should keep a distance of at least 500mm with the surrounding objects to avoid collision.

Fine Mesh Replacement

1) Loosen the 6 pcs plastic black knobtoremove the upper hopper and sieve frame set.

2) Loosen the tensioning clamp, remove the broken mesh

3) Put the new fine mesh horizontally.

4) Press the tensioning ringdevice vertically into the annular groove at the bottom and

fasten it firmly.

5) Repeat the above steps and press the tensioning ring deviceinto the upper annular groove.

6) scissors cut theexcessive mesh.

Maintenance

·Cut off the power when not in use.

· It is prohibited to rinse the motor when cleaning the machine to prevent electric leakage.

·Keep the screen clean; use corresponding detergent according to the filter material; meanwhile it is prohibited to crash the screen with shape or hard objects to prevent damage.

·If any abnormal sound is found during use, please stop to check the machine immediately.